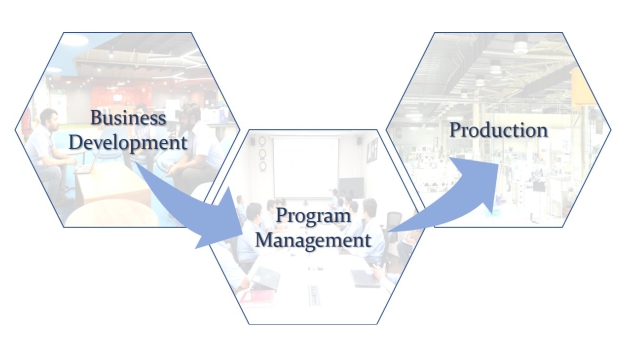

PROGRAM MANAGEMENT SYSTEM

Our globally benchmarked Program Management Processes ensure customers are treated to an experience of certainty, reliability and repeatability, every time, all the time. Our metrics are proactive and through the Program Management Communication Tool we provide visibility of metrics to customers, so that opportunities and risks are identified early and mitigation actions are planned in advance.

LEAN MANAGEMENT

At our facilities, we utilise a combination of Lean concepts to enhance efficiency of the processes involved. Our methods for Waste Minimization allows us to perform tasks economically. Smart factory based approach is employed to part development and engineering to achieve First Time Right Industrialization. Our shopfloors are geared up for Industry 4.0 with real-time MES, automated tool management, digital Poka-Yoke, SPC driven quality control for optimisation and predictive maintenance of machines.

SAKSHAM: PRODUCTION SYSTEM

Our Production System – SAKSHAM, has been developed with a Vision – ‘Certainty to our Customers. Efficiency to Us’. SAKSHAM in Sanskrit means 'Capable' and the system is geared to reflect its meaning. SAKSHAM provides a framework for our projects to ensure implementation through stages of planning, building, maintaining, improving & sustaining. It is a blend of the widely implemented concepts of lean, standardization, waste reduction, risk mitigation, opportunity & process adherence.

GATED PROCESS

Tata Advanced Systems has a customer-centric documented gated process. This includes detailed review processes and checklists that ensure consistency in delivery throughout the program life cycle from lead generation to steady-state delivery of the program. The gated approach is aided by our robust project tracking and reporting system to ensure complete visibility of the program across all levels and cascading of common goals.